unblocked games

unblocked games

unblocked games

FDP Manufacturer

Trusted False Deck Panel Developer

Advanced Structures Corporation is a premier manufacturer and nationwide distributor of False Deck Panels (FDPs) for the Navy.

But what exactly is an FDP? FDP stands for False Deck Panel—a type of raised flooring system that creates an elevated platform with a concealed space underneath. This hidden gap allows for the efficient routing of electrical and mechanical systems, making it an essential component for operational functionality aboard Navy and Coast Guard vessels.

For more information about false deck panels and their benefits, please get in touch with us. When you reach out, we can provide you with a free no-obligation consultation. When you turn to Advanced Structures Corp, you are getting the most for your money!

Contact Us for More Information

Advanced Structures Corporation has years of experience in the industry and has become a trusted FDP distributor. We are an in-house manufacturer with the ability to distribute to customers nationwide. And since we are an in-house manufacturer, we have the ability to easily customize your false deck panel to adhere to your specifications.

Request a Quote

We are a leading developer and manufacturer that specializes in lightweight honeycomb doors and panels for US Naval and US Coast Guard applications. For more information, please reach out to us today. We will happily answer any and all questions pertaining to Navy false deck panels. Our staff can also provide you with a free quote for your potential order.

Different FDP Finishes Available

Different FDP Finishes Available

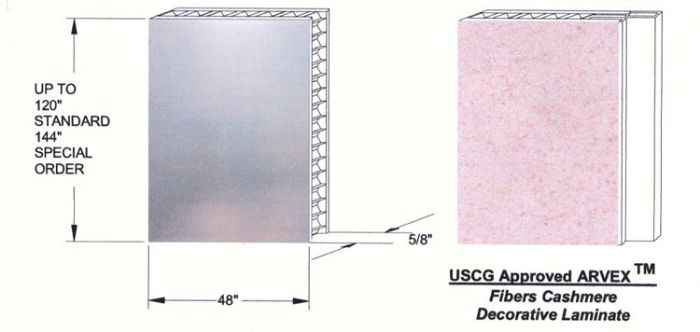

We offer a variety of false deck panel options to choose from during the manufacturing process. So you have the opportunity to select the one that best fits your needs. Three decorative finishes are available:

These various finishes add another dimension to the FDP in total. When choosing, you have the option to select the one that works best for you!

Custom FDP Orders

As an in-house false deck panel manufacturer, we have the ability to custom make orders to specifically adhere to your specifications. Each FDP is manufactured in strict accordance to Bath Iron Works Catalog No. 57015-012. The Certificate of Conformance is based on the Bath Iron Works approvals of our Test Report (ASTR-208) under the Bath Iron Works Letter 1843-1/JRT, which is dated 3/7/1991 and an approval dated on 4/11/1995.

Here are the various accordance we follow to ensure that our false deck panels are up to code.

- .536-.500 thick, 48" x 96"

- Honeycomb Core: 3/16" cell, 6.0 lb. density with 20 mil 7642 fiberglass composite layers impregnated with 50% by weight Fire Retardant Phenolic resin

- MIL-A-25463 Non-Hydroscopic Adhesive

- Faced with customer specified decorative finish

- Bonded together as a composite structural panel

Importance of Custom FDPs for Ships

Custom false deck panels play a critical role in the design, safety, functionality, and maintainability of ships. Here is a breakdown of their importance.

Safety and Fire Protection

A custom FDP can be made from fire-resistant materials to help contain and delay the spread of fire. On top of that, these panels can be designed with anti-skid coatings, reducing the risk of accidents during movement onboard.

Functional Flexibility and Access

False deck panels provide a concealed space for routing electrical wiring, piping, HVAC ducting, and data cables. This keeps the main deck clear and better organized. When custom panels come into play, they can be designed for easy removal, allowing maintenance crews quick access to vital systems without major disruptions.

Mission-Specific Customization

Depending on the type of ship, there will be different requirements. A custom FDP can support mission-specific needs such as equipment mounting, data hubs, or storage access. On top of that, these panels can be sealed against water, dust, or corrosion for sensitive equipment in harsh marine environments.

Modular Design and Upgradability

Coast Guard and Naval ships are often upgraded or reconfigured vessels. So, custom panels allow for easy integration of new technologies or re-routing systems without full overhauls. An FDP can also be tailored to optimize weight distribution and maintain vessel stability.

Maintenance Efficiency

Custom panels can include inspection windows or access points tailored to the ship’s layout, which will improve the efficiency of a routine inspection. And if an individual FDP is damaged, then it can be replaced without affecting the entire deck. Continuing on the trend of efficiency.

Acoustics and Vibration Damping

Overall, a custom false deck panel can integrate sound-absorbing materials, which reduces noise and vibration levels within crew areas and operational spaces. That is crucial for stealth and comfort.

In the end, custom false deck panels are integral to efficiency, safety, and adaptability of a Coast Guard or Naval ship. Proper FDPs allow shipbuilders and operators to future-proof their vessels while meeting stringent marine regulations and operational demands.